Key Technical Applications of SKL Bearings in Hoisting and Conveying Machinery —

I. Case Background

Founded in 1992, a certain heavy industry group is the world's largest manufacturer of container cranes. In its early days, the domestically - produced bearings supporting the gearboxes of the trolley traveling mechanism and luffing mechanism of quay container cranes exposed three core problems in actual operation:

· Frequent Failure of Bearings in Trolley Traveling Mechanism: The common deep - groove ball bearings had insufficient sealing performance, leading to sand and sediment invading the raceways and lubricating grease becoming contaminated and ineffective. Bearings had to be shut down and replaced every 300 hours on average, with a failure rate as high as 35%. The capacity loss caused by a single shutdown exceeded 100,000 yuan.

· Severe Raceway Spalling of Bearings in Luffing Mechanism Gearbox: The gearbox bears alternating impact loads, and the supporting domestically - produced tapered roller bearings had insufficient impact resistance. The raceway spalling rate reached 38%, and the continuous operation time was less than 100 hours, which seriously affected the luffing accuracy of the crane.

· High Maintenance Costs: Traditional bearings had short service life and high replacement frequency. The annual cost of bearing replacement and shutdown maintenance for a single crane exceeded 500,000 yuan. Moreover, frequent disassembly aggravated the wear of equipment structural parts and shortened the service life of the whole machine.

II. SKL Customized Solutions

To address the technical pain points of the heavy industry group, SKL provided an integrated solution of "Bearing Customization + Lubrication Optimization + Sealing Upgrade", with two core high - performance bearing products as supporting parts.

(I) Trolley Traveling Mechanism: SKL 22318 - E1 - T41A Spherical Roller Bearings

1. Product Technical Features:

o Structural Innovation: Adopting the design of solid outer ring with spherical raceway and symmetrical barrel rollers, it has self - aligning function, which can compensate for shaft misalignment caused by frame deformation or installation errors (the maximum self - aligning angle can reach 2.5°), avoiding roller eccentric wear.

o Enhanced Sealing Design: Equipped with double - lip fluororubber sealing ring and labyrinth dust - proof structure, the protection grade reaches IP65, which effectively blocks the intrusion of dust and salt spray and solves the problem of lubricating grease contamination.

o Material and Heat Treatment Optimization: The rollers are processed by carburizing and quenching, with the surface hardness reaching HRC62 - 64, which improves the resistance to pitting corrosion and spalling by 40%. The cage is made of high - strength brass material, which is suitable for high - frequency impact loads.

2. Lubrication Scheme Upgrade: Equipped with SKL special high - temperature long - acting lubricating grease, it can work stably in the temperature range of - 20℃~120℃. The lubrication cycle is extended to 2000 hours, which is 6 times longer than the service life of traditional lubricating grease.

(II) Luffing Mechanism Gearbox: SKL 21320 - E1 - TVPB Spherical Roller Bearings

Product Technical Features:

· Ultimate Load - Bearing Capacity: Adopting reinforced roller design (E1 type), the rated dynamic load reaches 1280kN, and the rated static load reaches 1850kN. It can withstand 1.8 times the rated load impact, solving the problem of raceway spalling under alternating loads of the gearbox.

· High - Precision Manufacturing: The diameter tolerance zone is controlled to ISO P5 grade, with high rotation accuracy, which effectively reduces the operation noise of the gearbox (the noise value is reduced from 85dB to 72dB).

· Corrosion - Resistant Treatment: The surface of the outer ring is treated with galvanizing and passivation. No rust occurs in the salt spray test (5% NaCl solution, spray time 480 hours), which is suitable for the high - salt - spray environment of ports.

III. Application Effects: Dual Breakthroughs in Performance and Economic Benefits

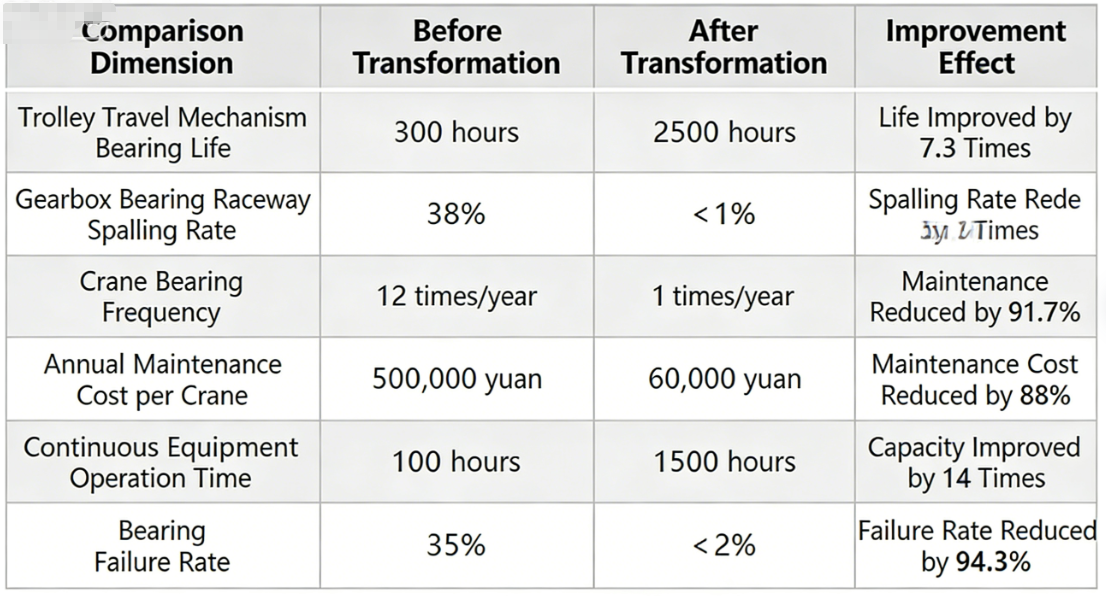

Since the heavy industry group adopted the SKL bearing solution, through 6 months of actual operation verification, the equipment performance and economic benefits have been significantly improved. For specific data comparison, refer to the table below:

In addition, the self - aligning function of SKL bearings effectively compensates for the deformation error of the crane frame, improves the operation stability of the trolley traveling mechanism, and reduces the wheel rail gnawing phenomenon by 80%. The vibration value of the luffing mechanism gearbox is reduced from 7.8mm/s to 2.2mm/s, and the equipment operation noise is significantly reduced, improving the port operation environment.

IV. Core Technical Advantages of SKL Bearings in Hoisting and Conveying Machinery

1. Heavy - Duty Impact - Resistant Design: Aiming at the alternating load characteristics of hoisting machinery, SKL spherical roller bearings adopt symmetrical barrel rollers and optimized raceway curvature radius, which makes the load evenly distributed over the entire length of the rollers, and the impact load resistance is improved by more than 50% compared with traditional bearings.

2. Adaptability to Harsh Environments: Through the combination of sealing structure innovation, surface corrosion - resistant treatment and long - acting lubrication scheme, SKL bearings can adapt to extreme working conditions such as port salt spray, metallurgical dust and mine mud, and greatly extend the maintenance cycle.

3. Ease of Installation and Maintenance: SKL bearings adopt standardized size design, which can directly replace the same model of domestic or imported bearings without modifying the equipment structure. At the same time, it is equipped with an intelligent recording system, which allows users to quickly query product installation dimensions and load parameters, reducing the cost of technical docking.

Conclusion

Against the backdrop of the rapid development of the global logistics industry, the demand for high - efficiency, reliability and low maintenance of hoisting and conveying machinery is becoming increasingly urgent. With its precision craftsmanship made in Germany and customized solutions, SKL bearings have successfully solved the bearing failure problem of hoisting machinery under heavy - duty and harsh working conditions, creating significant economic benefits for equipment manufacturers and end users.