Key Technical Applications of SKL Bearings in Construction Machinery — Taking a

I. Case Background

A large iron ore enterprise’s core crushing equipment — the PE1200×1500 jaw crusher — undertakes the key task of primary crushing of raw ore. Operating in an open-pit mine environment with high dust concentration and frequent impact loads, the original supporting bearings have long faced early failure issues, becoming a core bottleneck restricting production efficiency.

Core Equipment Issues

· Extremely short bearing service life: The original domestic bearings have an average service life of only 6 months, far below the industry average. Frequent shutdowns for replacement are required, with a single maintenance shutdown lasting up to 8 hours, seriously affecting the continuous operation of the crushing production line.

· Poor operational stability: Affected by ore impact and shaft deflection, the bearing vibration value is high, leading to increased overall equipment vibration, which impairs crushing accuracy and structural stability.

· High energy consumption and maintenance costs: Frequent bearing replacements have caused a surge in labor and spare parts costs. At the same time, excessive vibration has increased the equipment’s energy consumption per ton of ore, placing significant operational pressure on the enterprise.

II. SKL Customized Solution

The SKL technical team conducted in-depth on-site research at the mine, and after comprehensive testing of equipment load data, operating temperature, and vibration parameters, developed a customized solution centered on "high-performance bearings + seal upgrade + full-process service":

· Core bearing selection: Recommended the SKL 231/600-K-MB spherical roller bearing, designed specifically for heavy-duty crushing equipment. It features ultra-high radial load capacity and excellent self-aligning performance. The "K" denotes a tapered bore design for easy installation and disassembly; "MB" indicates a brass cage, which enhances high-temperature and high-speed performance, adapting to the low-speed, heavy-load operating characteristics of the jaw crusher’s main shaft.

· Seal system upgrade: Equipped with SKL composite labyrinth seal components, adding a polymer dust lip to the original seal to form a "labyrinth + contact" double seal, blocking ore dust from entering the raceway.

· Lubrication scheme optimization: Adopted high-temperature synthetic grease, which maintains stable viscosity in dusty environments. Combined with the bearing’s optimized lubrication grooves, it achieves uniform grease distribution, doubling the lubrication cycle compared to the original scheme.

· Full-process technical support: SKL engineers provided on-site guidance for bearing installation and preload adjustment to ensure installation accuracy; offered a vibration monitoring scheme to track bearing operation status in real time and formulate preventive maintenance plans.

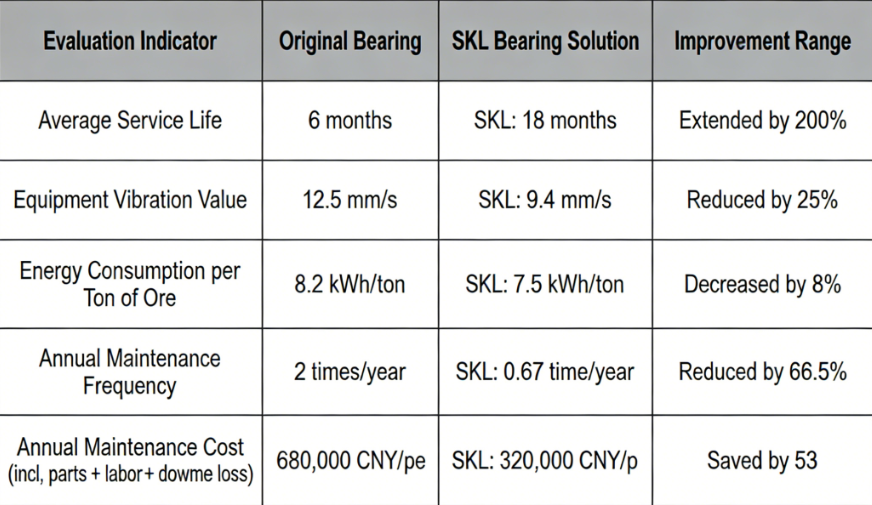

Implementation Effects and Core Data

After the implementation of this solution, the operating status of the jaw crusher’s bearings has been fundamentally improved. The core effects are fully verified by the following data (see the table for specific comparisons):

The equipment manager of the iron ore enterprise stated:"SKL’s bearing solution not only completely solved the long-standing bearing failure problem of the jaw crusher but also created significant economic benefits by extending the operation cycle and reducing energy consumption. A single piece of equipment gains over 48 hours of additional effective production time annually."

III. Industry Extension: Wide Application of SKL Bearings in Construction Machinery

Beyond jaw crushers, SKL bearing technologies have been widely adapted to core components of various construction machinery:

· In a certain EC500 crawler excavator, its automatic lubrication system and slewing bearing ensure stable operation during heavy-load crushing operations, improving fuel efficiency.

· In the wheel hubs and suspension systems of mining dump trucks, SKL large tapered roller bearings and spherical roller bearings bear the vehicle’s weight and bump impacts, ensuring driving safety.

· In roller presses and vertical mills on cement production lines, SKL high-temperature bearings and seal solutions adapt to high-temperature and dusty working conditions, increasing equipment operation rate to over 95%.

IV. Conclusion

The efficient operation of construction machinery relies on technological breakthroughs in core components. Supported by four core technologies (material, structure, sealing, and customization), SKL bearings not only solve the problem of bearing failure in extreme environments through condition-matched solutions but also achieve multiple values: "extending service life, reducing costs, and improving efficiency." From iron ore crushers to large excavators, SKL bearings, with data-verified excellent performance, have become an important support for reliability upgrades in the construction machinery field. In the future, they will continue to drive green and efficient industry development through technological innovation.